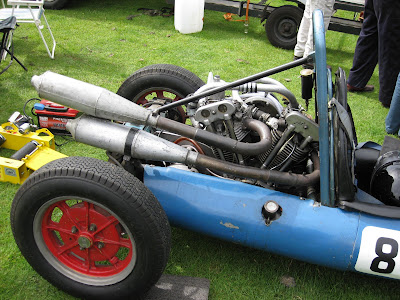

Had a grand day out at the local hill climb , everything from bikes to bugattis, but mainly it was Formula 500 cars from the 1950,s tiny little rceing cars with JAPs and Manx nortons in the back all running on methanol the heady scent of castrol R in the air!

But one thing that struck me was the shockng quality of some of the casting on these cars, but also on some real high performance exotics

Take alook at these wheels sand cast on the beach i think!

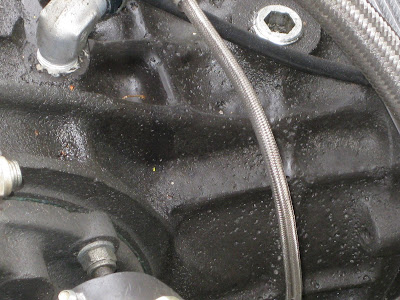

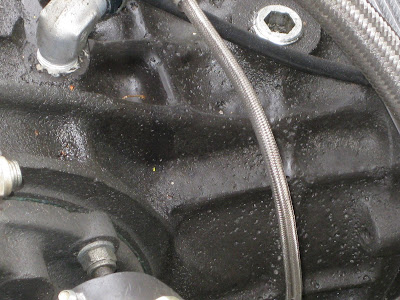

But also this diff caseing a magnisum hewland i think it was on Maclaren formula 5000.

But alos the important thing to note is some of these cars are 60 years old and still going strong!

been a tough and dishartening week, hoped to have the jack sahaft done and made a start on the SA by now as it is ive finaly maged to drill the 16 holes in the 2 sprockets! still that is progress can assemble the jack shaft at last, whilst waiting for parts ive been building the above recumbent trike for my nephews, but need to sort out some brakes before i let them lose as thers lots of hills here and this thing is fast!

been a tough and dishartening week, hoped to have the jack sahaft done and made a start on the SA by now as it is ive finaly maged to drill the 16 holes in the 2 sprockets! still that is progress can assemble the jack shaft at last, whilst waiting for parts ive been building the above recumbent trike for my nephews, but need to sort out some brakes before i let them lose as thers lots of hills here and this thing is fast!